Cadenza aims for mass production with China deal

eeNews Power Management

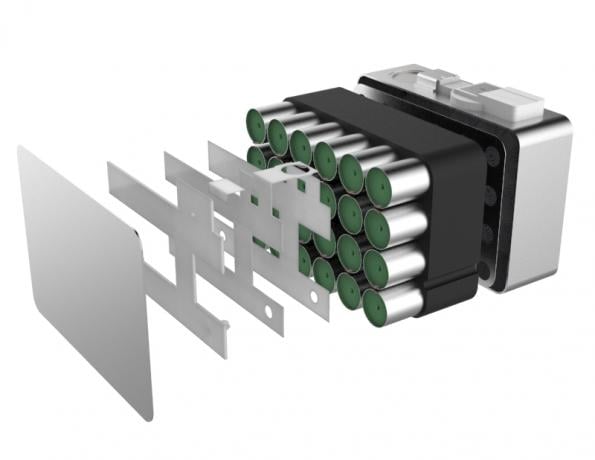

Shenzhen BAK Power Battery will manufacture Li-ion cells and modules based on Cadenza Innovation’s supercell architecture, which provides higher safety, lower cost and higher energy density by combining small ‘jelly roll’ cells in a ceramic material to create larger cells.

Before agreeing the deal, the companies carried out project feasibility assessments and safety testing, institutional testing and other third-party testing. The project teams in the US and China will promote the further market application of cells and modules based on the supercell design.

The technology has been tested as part of a US ARPA-e programme Fiat Chrysler Automobiles (FCA) used a Fiat 500e EV platform to test the supercells while the ceramic was supplied by Morgan Advanced Materials, originally developed to fireproof the “black boxes” used in aircraft. US lab NREL contributed thermal modeling expertise to confirm that the supercell system could prevent cascading thermal runaway.

“As a well-known domestic lithium battery company, BAK has always focused on quality while continuously innovating its products through independent research and development on the premise of ensuring the safety of batteries,” said Li Xiangqian, chair of BAK. “At the same time, we are also aware of the importance of continuously incorporating innovative technologies from at home and abroad. Cadenza Innovation’s new battery module architecture can effectively improve the safety of Li-ion batteries, while achieving higher energy density and lower energy costs. Through this partnership, this innovative technology will be commercialized by both parties. BAK will drive the successful realization of global industrialization of the supercell technology, which we believe will have a profound impact on the lithium battery and electric vehicle industry through the success of this cooperation.”

BAK has over 10 years of lithium battery production experience with more than 1,000 technical patents in its portfolio and its own novel manufacturing technology. The construction of the BAK supercell and module production line is underway in Zhengzhou BAK Industrial Park. It is expected that mass production will beoperational early in 2019.

The company has two production bases, Shenzhen BAK Power and Zhengzhou BAK Battery, producing batteries, modules and packages for passenger cars, buses, logistics vehicles and special vehicles. By December 2017, the company’s power battery capacity had reached 8GWh in 110,000 vehicles.

Related stories: